Road salt is a serious problem for vehicle owners located in snow belt states. Road salt makes roads safer by melting slippery ice and snow. However, it is also highly corrosive to vehicle frames, bodies and metal components. The corrosive process often can’t be stopped once it’s started. Preserving a vehicle’s integrity means cleaning road salt off the body and undercarriage on a regular basis. But what’s the best way to protect cars from road salt? Real Clean Salt Mitigation from Reliable Plus not only cleans, it leaves a protective coating that lasts until the next wash.

Road salt is a serious problem for vehicle owners located in snow belt states. Road salt makes roads safer by melting slippery ice and snow. However, it is also highly corrosive to vehicle frames, bodies and metal components. The corrosive process often can’t be stopped once it’s started. Preserving a vehicle’s integrity means cleaning road salt off the body and undercarriage on a regular basis. But what’s the best way to protect cars from road salt? Real Clean Salt Mitigation from Reliable Plus not only cleans, it leaves a protective coating that lasts until the next wash.

The Best Defense to Protect Cars from Road Salt

Salt Mitigation is a dual-purpose product. It cleans using selected builders and surfactants that target, neutralize and remove salts and other dirt and grime from the vehicle’s surface. Once the surface is clean, Salt Mitigation chemically bonds with metal surfaces to create a barrier film. This barrier protects against salt and moisture corrosion. It bonds to a variety of metal surfaces including cast iron and aluminum, steel, and copper.

Real Clean Salt Mitigation is designed to be used regularly for continuous protection from the corrosive effects of salt. Once a vehicle is coated it becomes easier to clean. This is because a hydrophobic film is being adhered to the surface. It allows the vehicle to resist buildup of additional rust and dirt.

Salt Mitigation Testing

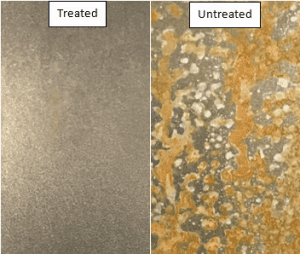

Real Clean put its Salt Mitigation to the test by simulating winter conditions in its laboratory. Most municipalities in the rust belt use a 20-percent calcium/magnesium chloride brine to keep roads free of ice and snow.

Real Clean chemists used a super-saturated version of this mixture to test its Salt Mitigation product, bumping the formula up to 30-percent calcium/magnesium chloride. Then, the mixture was sprayed on cold-rolled steel automotive panels. One panel was coated with Real Clean Salt Mitigation, one was left uncoated.

Both panels were exposed to five cycles of the 30-percent brine solution with drying time allowed between application. Afterward, the panels were then rinsed and allowed to dry for two days. At the conclusion of the test, the untreated panel showed significant rust formation. The panel treated with Real Clean was virtually rust-free.

Real Clean is available in 5 and 30 gallon containers. Contact us today to learn more or place an order!